Materials science has made leaps in recent decades, particularly with the discovery and manipulation of two-dimensional (2D) materials—ultrathin sheets of atoms with unique electronic and magnetic properties. Everything began with the discovery of graphene in 2004, a single layer of carbon atoms with exceptional electrical and mechanical properties. Researchers in Manchester were able to separate a single layer of carbon from its bulk crystal using household sticky tape.

Building on this discovery, researchers began exploring other 2D materials, broadening the possibilities of material science. In the beginning, only a handful of materials were known and used for research. In addition to metallic graphene and insulating hexagonal boron nitride (hBN), more and more materials have been discovered, including magnetic materials, semimetals, and superconductors.

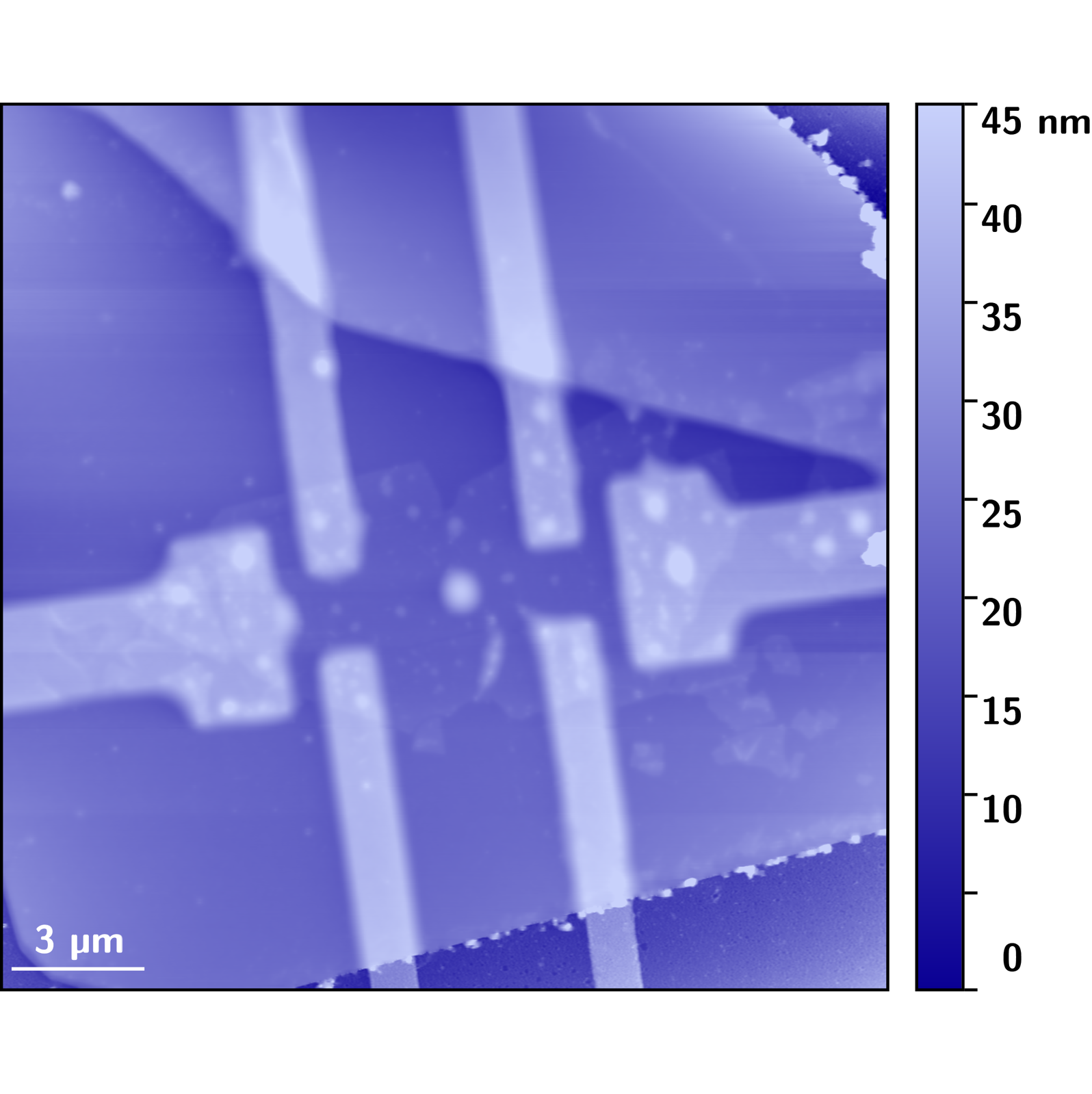

By stacking different 2D materials on top of each other, scientists can create van der Waals heterostructures. These engineered materials offer unprecedented control over electronic and optical properties, leading to significant advancements in electronics, quantum computing, and spintronics., named after the weak interlayer forces that hold them together. These structures allow researchers to tailor new materials with properties that do not exist in nature, leading to advancements in electronics, quantum computing, and spintronics. While the initial methods for creating artificial crystals were highly complex and had limited success, this changed with the introduction of the PDMS-PC dry stacking technique. A device that was created using this technique is shown in Fig. 1. The bulk material images were taken from the website of the Quantum Materials Lab of the University of Arkansas which provides a great overview of exfoliatable materials.

Before constructing these heterostructures, researchers must first prepare the thin crystal sheets. Using adhesive tape, thin flakes of layered crystal are peeled from a bulk crystal. Basically, the thickness of the crystal pieces is halved with every iteration of opening and closing a piece of tape. Instead of the household scotch tape, researchers nowadays employ blue tape. This tape type of tape is usually used to cover example items to protect their surfaces and is used by researchers due to its low adhesive residues. The process is shown in Fig. 2. These flakes are then transferred on silicon wafers and inspected under an optical microscope to identify those with the right thickness and quality.

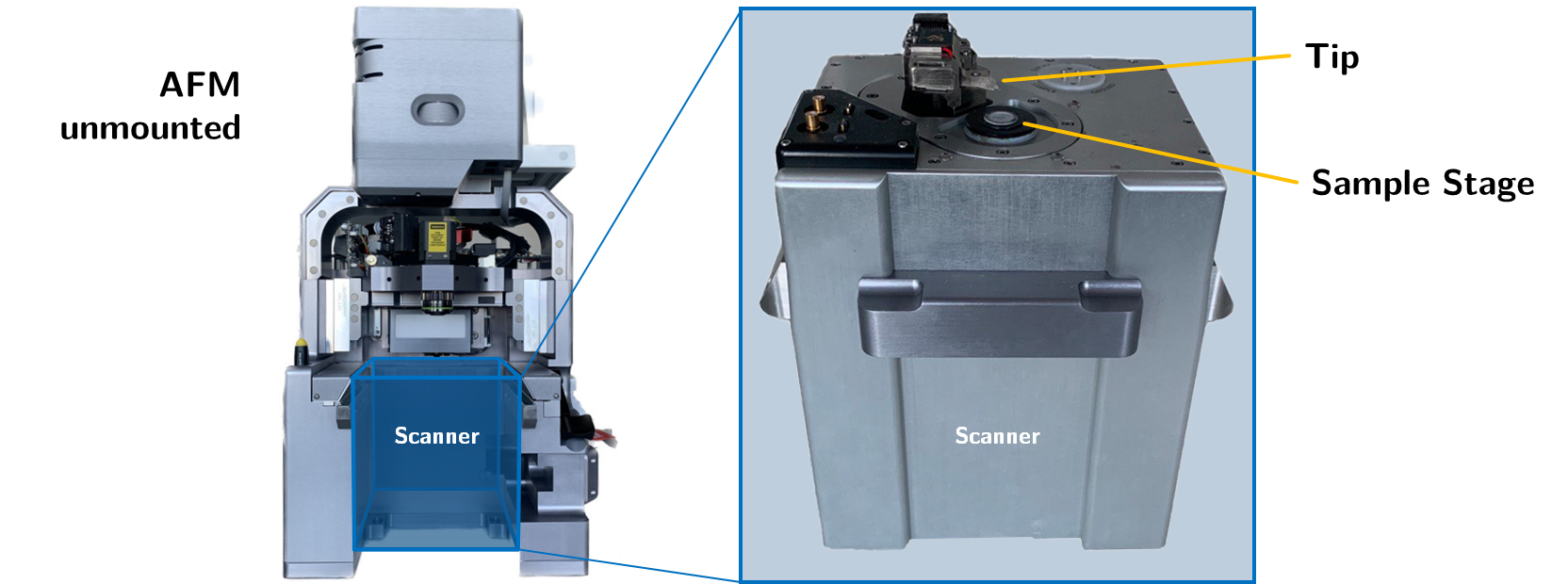

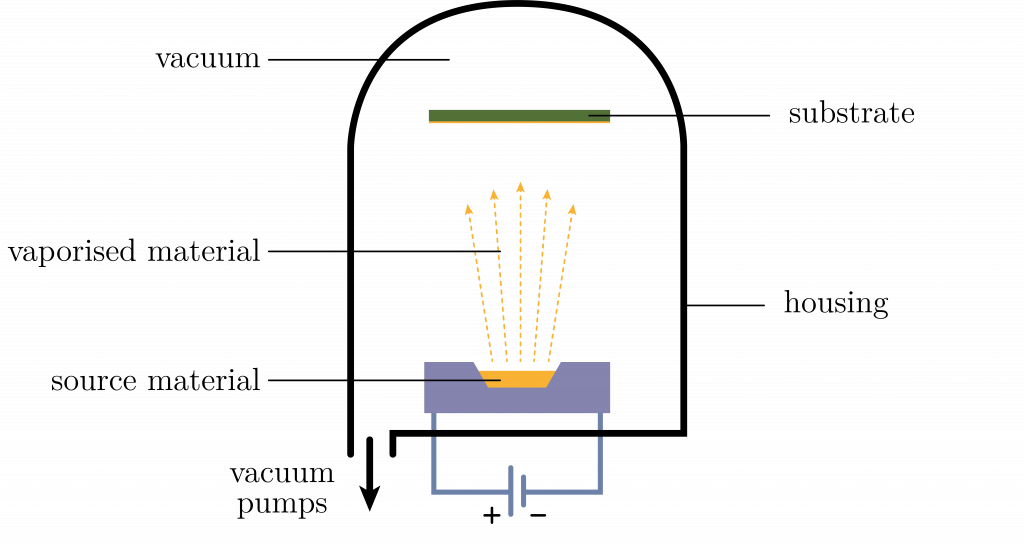

With the selected flakes in hand, researchers use the PDMS (polydimethylsiloxane)/PC (polycarbonate) Dry Transfer method to assemble artificial crystals layer by layer, ensuring precision and purity. As illustrated in Fig. 3, this process involves several key steps that allow for high control over layer alignment and minimal contamination.

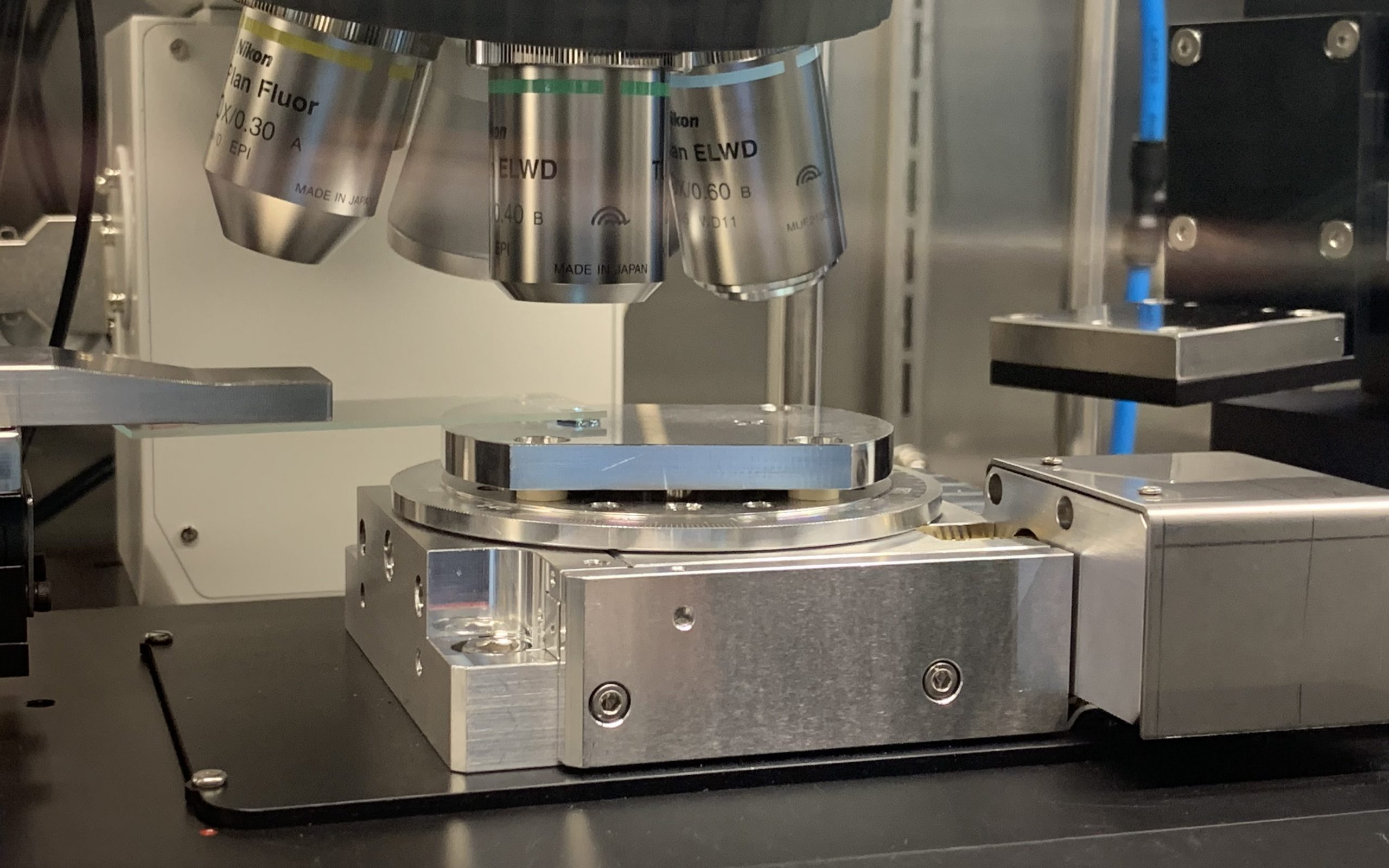

A PDMS stamp coated with a thin layer of PC is used to pick up an exfoliated 2D material. This stamp is then aligned over the target substrate under a microscope. By carefully controlling the temperature and pressure, the material is released onto the stack without contamination. The polycarbonate layer is later dissolved, leaving a clean heterostructure. This dry transfer method provides a high level of control over layer alignment and minimizes impurities, making it an essential tool for studying and engineering advanced 2D material-based devices. Following, the steps are described in more detail:

- Flake Selection and Alignment: A PDMS stamp coated with a thin layer of PC is first aligned over a selected 2D material flake using a microscope. This step ensures precise positioning of the flake for pickup.

- Flake Pickup: The stamp is gently pressed onto the flake while applying mild heat. This softens the PC layer, allowing the flake to adhere to it. Once lifted, the flake is securely attached to the stamp.

- Stacking Multiple Layers: The pickup process can be repeated to stack multiple flakes on top of each other. Typically, only the first flake requires heat; subsequent flakes attach through van der Waals forces alone.

- Substrate Transfer: After assembling the desired stack, the PDMS-PC stamp is moved to a different substrate, such as a silicon wafer or a pre-patterned chip with electrical contacts.

- Final Alignment and Deposition: The flake is carefully positioned over pre-fabricated electrical contacts and deposited at temperatures above 160°C, which ensures good adhesion and minimizes contamination.

- Polycarbonate Removal: The PC layer is dissolved using chloroform, leaving behind a clean, high-quality van der Waals heterostructure, ready for further experiments or device fabrication.

Ultimately, van der Waals heterostructures serve as a foundation for next-generation nanotechnology, enabling innovations in data storage, high-speed electronics, and beyond. From spintronic devices that store information using electron spin to high-speed, ultra-efficient transistors, these materials push the boundaries of what is possible. By refining fabrication techniques, researchers can fine-tune these structures to develop new quantum materials, flexible electronics, and energy-efficient computing devices. As our ability to design and manipulate materials at the atomic level continues to improve, van der Waals heterostructures will remain at the forefront of scientific and technological breakthroughs.